Online Dewpoint Meter

Optimal for trace humidity measurement The Testo humidity sensor is generally calibrated at several points to ensure minimum deviations. For trace humidity measurement, a high-precision reference measurement (dew point mirror) is used to help carry out a calibration at -40 °CtP (pressure dewpoint)

The ideal operating concept

Does the unit have to be changed from °Ctpd to ppmV or do the operating points need to be corrected? These and many other settings can be easily configured via the display. Or - and this is particularly advantageous for OEM customers such as manufacturers of compressed air dryers - these adjustments can be handled by a PC running the scaling adapter software 0554.3305, even without a display.

Features and benefits

- Maximum reliability

- Long-term stability, testo humidity sensor applied 100,000 times over

- Demonstrably correct indication of measurement ranges and data

- Highest manufacturing quality

- Calculation of the most important trace humidity variables e.g. °Ctpd, °Ctd atmospheric, ppmv

- Calibration protocol

- Convenient operation

- Via the display menu without additional aids

- Without display via the internal interface and scaling adapter software (cf. p. 6) - Local 1-point Calibration

Compressed Air Flow Meter

The Testo 6440 series of compressed air flow meters is designed to monitor, measure and record compressed air consumption to aid in the determination of leakage, consumption-based allocation of costs and the implementation of peak load management. The 6440 series utilizes the calorimetric principle so that the measurement procedure is independent of the process pressure and does not cause a permanent pressure drop. While the thermal, glass-coated ceramic sensor offers a high level of robustness and fast response times, the integrated inflow and outflow pipes ensure optimum accuracy.

Features

- For the measurement of compressed air

- Available in four sizes from 1/2” to 2” with flow ranges from 0.25-75 m3/h to 2.3-700 m3/h

- Accuracy: up to ±3% of measured value, ±0.3% of final value

- Selectable units: m3/h; l/min; m3

- Thermal, glass-coated ceramic sensor (calorimetric measurement procedure)

- Temperature range: 32 to 140 °F

- Outputs

- 4 to 20 mA (4-wire) analog output

- Pulse output

- 2 switch outputs, parameterizable

- Supply voltage: 19 to 30 V DC

- 4-digit alphanumerical display with two operating buttons, operating menu, and LEDs

- Process pressure: PN 16 (max 16bar/232psi)

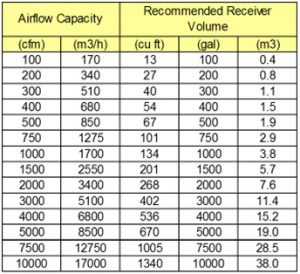

Compressed Air Receivers

Supplied with all necessary safety fittings. When using an intermittent air supply they act as a buffer and a storage medium which allows the distribution system to temporally sustain an air consumption which can be slightly higher that the capacity of the compressor.

Main Benefits

- Pressure stabilization

- Pulsation reduction

- Velocity reduction

- Temperature reduction

- Storage for handling high air consumption

- Improvement of the life, reliability and functionality of your compressed air system

- Condensate separation

Applications

Any application using compressed air systems

Range

Compressed Air Piping

Air piping is used to provide compressed air to the usage points. The compressed air requires to be delivered with appropriate quality, adequate volume, and pressure to accurately power the components that utilize the compressed air. Completely air tight and simple to mount, the range is ideal for installations requiring the highest quality air. These are energy efficient and do not require labor for installation. The range is best suited for compressor due to its nil leakage and nil corrosion features. Clients can avail this piping into various specifications to suit the industrial requirements.

Specifications:

- Reduce pressure from the pipes

- Reduce the vibrations

- Withstand high temperature

Features:

- Leak-proof

- Rust free

- Easy handling

- Affordable price

- Durability

Air Cooled After Cooler

After coolers are heat exchangers for cooling the means of removing moisture from compressed air. After coolers reduce the amount of water vapour in a compressed air system by condensing the water vapour into liquid form.

Salient Features

- Compact copper tube heat exchanger with Aluminium fins (ACC Series)

- Compact in design as per StdEnggpartice (WAV & WAH Series)

- Highly reliable fan motor (ACC Series), provided with finger Guard.

- Maximum inlet temperature 120° C

- 50% reduction of inlet temperature (If inlet is 90°C after cooler output shall be 45°C

Range

Air Cooled after Cooler 35cfm to 1000cfm

Horizontal Water Cooled 50cfm to 1500cfm after cooler

Vertical water Cooled 50cfm to 1500cfm after cooler